Description

Manufacturing Process

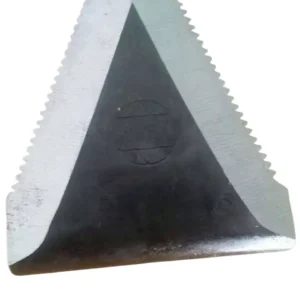

- Material Selection – High-strength alloy steel is used for durability and wear resistance.

- Cutting & Shaping – Steel sheets or bars are cut and shaped into the required cutter bar length.

- Blade Attachment – Knife sections or cutting teeth are attached using rivets or bolts.

- Heat Treatment – The cutter bar and blades undergo hardening and tempering to enhance strength.

- Surface Finishing – Coatings such as black oxide or zinc plating are applied to prevent rust and corrosion.

- Assembly – Moving components like knife guards and guide plates are installed for smooth operation.

- Quality Testing – The cutter bar is tested for sharpness, durability, and smooth movement before final use.

Reviews

There are no reviews yet.